Phone : +91-9827113763 | +91-7587733050

OUTPUT SIZE: 15mm to 350mm

PRODUCTION CAPACITY: Up to 800TPH

Quick Overview

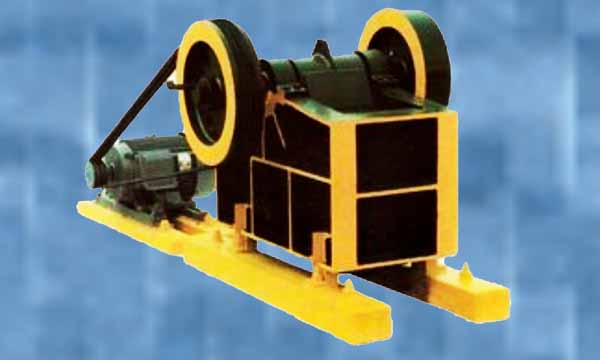

We are An ISO-9001:2015 Certified Company call: +91-9827113763 for wide range of Jaw Crusher Manufacturers in Delhi Indiah for rock & mineral processing equipment in the india. Since the 20th year, we've installed more than 1000 crushing plant all over the india. Nowadays, jaw crusher has already become the most popular equipment in the india without controversy. It is the first choice for hard and strong abrasion material.

Working Principle

The crushing method of jaw crusher is dynamic squeeze. The working principle is: the electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or split when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turns back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulkproduction is achieved while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

Performance

- High crushing ratio, uniform final product size;

- Deep crushing chamber without dead zone, which increase the feeding capacity and production capacity;

- Stable and convenient gasket discharge adjusting device makes the adjusting range wide and flexible;

- Safe and reliable lubrication system, easy replacement of wear;

- Simple structure, low operation costs;

- Energy saving, low noise and little dust.

Apllication

Sponge Iron Plant, Power Plant, Mining, Quarrying, Metallurgy, Building Material, Highway, Railway and Chemical Industry.

Features:

- Advanced movable jaw assembly

- Bearing with larger specification and higher load

- It adopts tire coupling with capability of flexible connection and stable operation.

- "V" structure crushing chamber

- Flexible adjusting ways of discharging opening

- Tooth-shape side plate

Jaw Crusher Used To Process Following Materials

- River Gravel

- Granite

- Basalt

- Quartz

- Iron ore

- Diabase

- Slag Processing Unit

- Limestone

- Coal Gangue

- Bentonite

- Medical stone

- Rock phosphate

- Manganese ore

- Iron ore

- Copper ore

- Gold ore

- Quartz

- Active Carbon

- Carbon Black

- Ceramic

- Coal

- All kinds of Mineral Stone

| Screen size | ********* (mm) |

| No. of Layer | ********** (Nos.) |

| Screen mesh | *******(mm) |

| Max. feed size | ******* (mm) |

| Handling capacity | ******** (t/h) |

| Vibrating frequency | ******* (r/min) |

| Power (kW) | ******* Power (kW) |